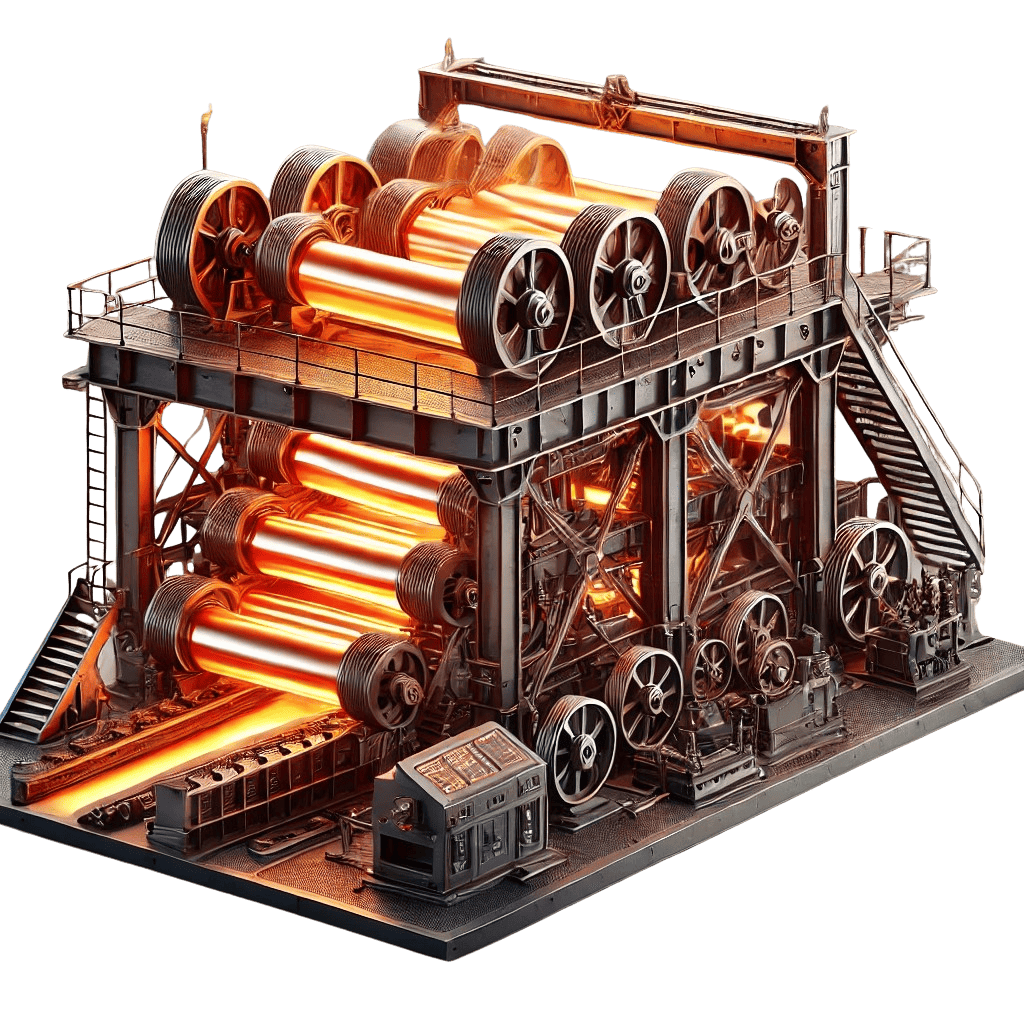

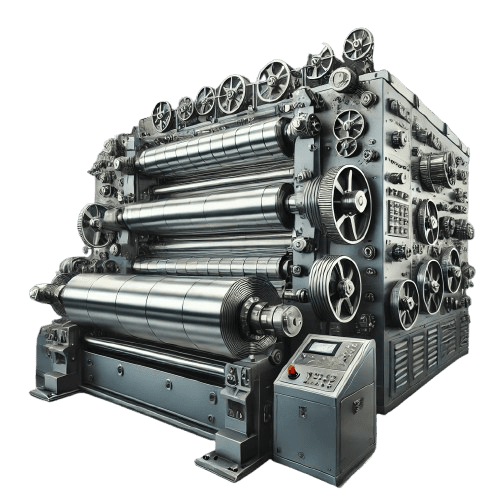

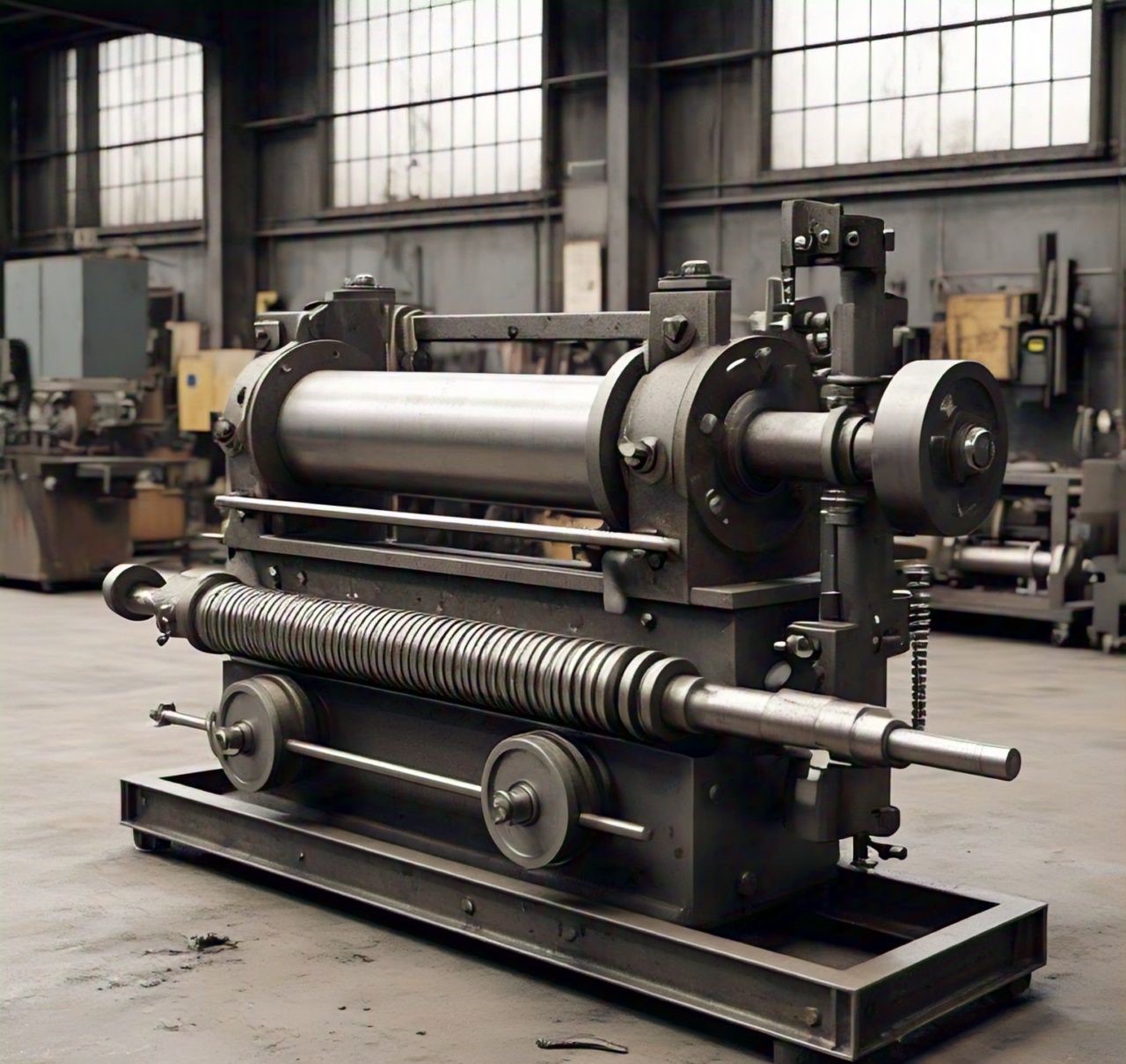

Purpose & Capabilities:

- -Primary Breakdown of thick aluminium slabs (up to 600 mm) into thinner intermediate gauges.

- -Achieves high-volume throughput crucial for large-scale production.

Technical Features:

- -Reheating Furnaces rated up to 650°C for optimum slab temperature.

- -Hydraulic Screwdowns providing real-time load control and precise thickness adjustments.

- -Rolling speeds up to 2000 m/min for maximum productivity.

- -Roll Gap Lubrication Systems to reduce friction and improve surface finish.

Typical Output:

- -Intermediate gauges from ~20 mm down to ~3 mm, ready for cold rolling or direct finishing.